CRACK MEASURING DEVICES

Crack Measuring Microscope

CRACK MEASURING MICROSCOPE WITH WF-10X FOCUSSABLE EYEPIECE

It is a precision instrument. The LED light source is adjustable on a swivel. The reticle can be focussed by moving the eye piece lens up or down. The object is focussed by rack & pinion movement. It is inexpensive substitute for conventional tools like micrometer, dial gauges. The measurements can be done with the microscope.

Technical Specifications :

It is a precision instrument. The LED light source is adjustable on a swivel. The reticle can be focussed by moving the eye piece lens up or down. The object is focussed by rack & pinion movement. It is inexpensive substitute for conventional tools like micrometer, dial gauges. The measurements can be done with the microscope.

Technical Specifications :

| Model | RCD-20 | RCD-40 | RCD-50 | RCD-60 | RCD-100 |

| Eyepiece | WF10x* Focusable | WF15x Fixed | WF10x* Focusable | ||

| Objectives | 2X | 4X | 5X | 4X | 10X |

| Magnification | 20X | 40X | 50X | 60X | 100X |

| Work distance* | 25mm | 15mm | 15mm | 15mm | 6mm |

| Field of view* | 8.2mm | 4.00mm | 3.2mm | 3.00mm | 1.7mm |

| Least count* | 0.050mm | 0.025mm | 0.020mm | 0.025mm | 0.010mm |

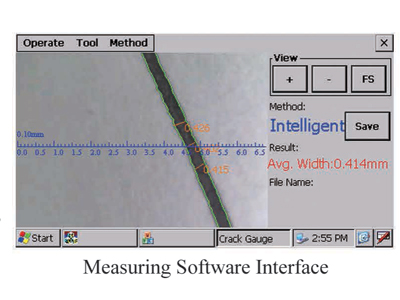

Digital Crack Measuring Microscope USBM-5S

USBM-5S Digital USB Microscope is a slim type handy tool.

USBM-5S Digital USB Microscope is designed for PC solution with friendly user interface. The special software: Micro-Measure-Tool can support you to have picture, record video and do Micro-Measure work with ease.

USBM-5S Digital USB Microscope is designed for PC solution with friendly user interface. The special software: Micro-Measure-Tool can support you to have picture, record video and do Micro-Measure work with ease.

SPECIFICATION :-

SPECIFICATION :-

| Image Sensor | - | 2.0 MP Color CMOS Sensor |

|---|---|---|

| Video Format | - | AVI |

| Photo Format | - | JPEG & BMP |

| Focus Range | - | Manual Focus from 15MM to 40MM |

| Focus Point | - | 50X & 500X |

| Video Capture Resolution | - | 640x480, 320x240 |

|---|---|---|

| Still Image Capture Resolution | - | 1600x1200, 1280x960, 640x480, 320x240 |

| Frame Rate | - | Max. 30F/S under600 Lux Brightness |

| Snapshot | - | Software & Hardware |

| Digital Zoom | - | 5X Sequence Mode |

| Brightness, Contrast, Saturation, Hue, Sharpness, Gamma Control | - | Manual Adjustment Auto W/B by Software |

| Light Source | - | In-Built White Light LED 8 PCS. (Adjustable by Control Wheel) |

| PC Interface | - | USB 2.0 & USB 1.1 Compatible |

| Power Source | - | 5V DC from USB Port |

| Measure Tool | - | Cooling Tech (It can measure length and diameters, angle, the perimeter, area etc.) |

| CD Disk | - | Driver & Cooling Tech Tool. |

| System Requirement | - | Pentium Computer with 700 HZ above, 20 MB HD Space, CD ROM Driver, 64 MB RAM, Direct X VGA Card |

| Operating System | - | WIN XP/VISTA/WIN7 32BIT & 64BIT |

| Language | - | English |

| Dimension | - | 112MM(L) X 33MM(R) |

| Product Net weight | - | 380G |

Electronic Crack Measuring Device RCD-WD

Crack Intergrated detector is mainly used for crack width and crack depth measurement of bridges, tunnels, buildings, roads and so on.

Main Features :

| Hardware Platform | Embedded ARM9 Hardware Platform, WinCe5.0 Operating System, True Color TFT Touch Screen | ||

| Crack Depth Test Range | Standard Probe : 0.01mm~6.5mm High Grade Probe 0.005mm~3.5mm | ||

| Crack Width Test Accuracy | Standard Probe: <+0.02mm; High Grade Probe: <+0.01mm; | ||

| Crack Depth Test Range | 10mm~500mm | Crack Depth Accuracy | <+5% |

| Image Storage Format | BMP or JPEG | Power Supply | Rechargeable Lithium Battery |

| Working Time | >28 Hours | Working Temperature | –10°C~+50° |

| Working Humidity | >90% RH | ||

Crack Width Gauge CW-401

Crack Width Gauge is used to measure the crack width in concrete buildings such as houses, roads

and bridges, etc

FEATURES :-

FEATURES :-

Improved model with waterproof, dust-proof and shockproof shell design.

Imported latest sensor chip is used, whose test accuracy is high

The main screen has a tick mark for direct reading.

The probe is equipped with night vision function, which can also be used in dark environment.

Built-in rechargeable polymer lithium battery, increasing the working time and service life

Technical Parameters:

| Host Parameters | - | Waterproof level: IP65 Screen size: 5 inches, LCD resolution: 640×480 |

|---|---|---|

| Volume | - | 195×140×45mm, Weight: 0.8kg |

| Measuring Range | - | 0.02 ~ 2.00mm |

| Reading Accuracy | - | 0.02mm |

| Magnification | - | 40 times |

| Minimum Indexing | - | 0.02mm |

| Power Supply Mode | - | Built-in polymer lithium battery |

| Connection Length | - | 2.5m |

| Host Weight | - | 0.8kg |

| Temperature | - | 10 °C ~ 40°C, Humidity: <90%RH |

| Packing Specification | - | Material : Engineering plastic, Volume: 420×140×335mm, Weight : 5kg |

Crack Depth Gauge CD-501

Crack Depth Gauge is based on the principle of acoustic diffraction to measure the crack depth of

concrete surface.

FEATURES :-

FEATURES :-

New upgraded wireless cloud transmission function.

The instrument is easy to operate, fast to master, no need for professional knowledge.

On-site testing is simple and fast, no need to manually interpret the acoustic parameters, directly display the crack depth.

It adopts three anti-shell design, waterproof, dustproof and shockproof.

High accuracy, the maximum error is not more than 2%-10% of the actual seam depth.

Use bracket test without scribing, accurate spacing, adjustable, greatly improving test efficiency.

Technical Parameters:

Technical Parameters:

| Host Parameters | - | Waterproof level: IP65, Screen size: 5 inches, LCD resolution : 640×480 Volume : 195×140×45mm, Weight : 0.8kg |

|---|---|---|

| Crack Depth Test Range | - | ≤ 500mm |

| Test Error | - | ≤ 5mm or 2% to 10% of the actual depth |

| Measurement Method | - | Standard measurement |

| Data Transmission Interface | - | Fast measurement (quick test stand) |

| Data Storage Capacity | - | USB |

| Data Transmission Method | - | 20,000 sets |

| Power Supply | - | Wireless cloud transmission (optional) |

| Temperature | - | 10 °C ~ 40°C, Humidity: <90% RH |

| Packing Specification | - | Large capacity lithium battery, Material: engineering plastic Volume: 420×140×335mm, Weight: 5.5kg |

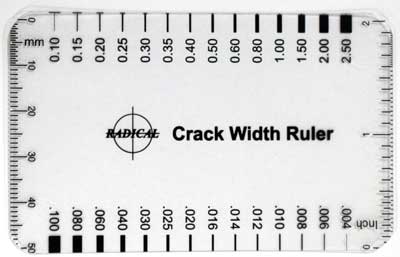

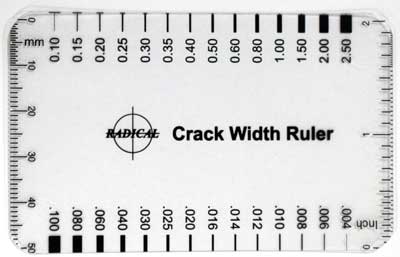

Crack Width Ruler RWR-7

The Simple Ruler Gauge designed to provide economical alternative to other graduated instruments used for Crack Width Measurement in concrete or any other type of material.

Clear resolution ensures fine details and accurate measurements. Made from premium quality, recyclable PVC, attractive and durable, this Crack Width Ruler is marked with a range of graded lines.

Clear resolution ensures fine details and accurate measurements. Made from premium quality, recyclable PVC, attractive and durable, this Crack Width Ruler is marked with a range of graded lines.

Each line has a specified width used to measure crack on all types of surfaces. Range Ruler A 0.10 to 2.50mm and B 0.004 to 0.100 inch.

Thick credit card size, easy to use and carry around in wallet or shirt pocket. Overall size of Width Ruler is 53 x 85mm.

For measurement, place the gauge over the crack and identify which line is of similar width to the crack. Read off the width value.

Each line has a specified width used to measure crack on all types of surfaces. Range Ruler A 0.10 to 2.50mm and B 0.004 to 0.100 inch.

Thick credit card size, easy to use and carry around in wallet or shirt pocket. Overall size of Width Ruler is 53 x 85mm.

For measurement, place the gauge over the crack and identify which line is of similar width to the crack. Read off the width value.

INSTRUMENTATION SINCE 1975 © 2024 Radical Scientific Equipments Pvt Ltd, All rights reserved