Metallography Equipment

Belt Polisher RBP-100 Series

Belt Polishers : For flat, Coarse grinding prior to fine grinding. The specimens to be ground in 60, 80 or 120 grit after cutting operation or moulding to remove surface imperfections. Useful step to remove light metallurgical damage in the specimen surface induced during cut-off operation.

Belt Surface Grinder RBPD-32 Series

Technical Specifications:

Distance between two rollers :- 255 mm

water cooling system and dust separation plant

water cooling system and dust separation plant

Belt :- 100mm width x 1000mm length

Rotation :- 1400rpm

Surface speed :- 760rpm

Motor :- 750W

Power :- 380V/50HZ

Dimension :- 580x600x980mm

Grinding Size :- 220x120mm .

Distance between two rollers :- 255 mm

Belt :- 100mm width x 1000mm length

Rotation :- 1400rpm

Surface speed :- 760rpm

Motor :- 750W

Power :- 380V/50HZ

Dimension :- 580x600x980mm

Grinding Size :- 220x120mm .

Manual Hot Mounting Machine RHM-30 Series

Technical Specifications:

Mould Diameter:- 30mm

Heat Specifications:- =800W

Temp. Adjustment Range:- 0-400°C

Power:- Single Phase 220V 50Hz

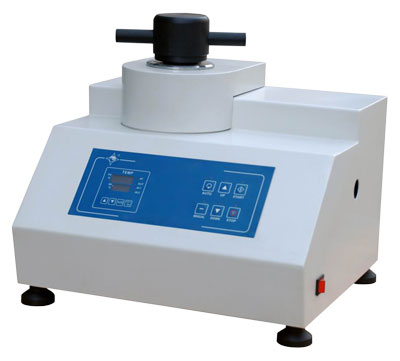

Digital Hot Mounting Machine RHM-2 Series

Automatic metallographic specimen mounting presses a kind of full automatic mounting press, equipped with in-out water cooling system. It is suitable for the heat mounting (thermohardening & thermoplastic) for all kinds of materials. After the parameters such as heating temperature, heat preserving time and applied force etc. are set up, put the specimen and mounting material into the machine, close the cover and press the start button, then the machine will finish the job automatically. It is not necessary for the operator to be on duty.

According to different requirements of the material, there are four kinds of moulds that can be chosen to meet the demands at will. Also it is available to prepare two pieces of specimens at the same time, the capacity is doubled.

Technical Specifications:

Diameter of specimen :- 30mm

Cooling method :- water cooling

Max. power consumption :- 1000W

Temperature setting range :- 0-300°C

Net weight :- 60Kg

Power supply :- 650W 220V, 50Hz

Dimension :- 570 × 520 × 670 mm

Technical Specifications:

Diameter of specimen :- 30mm

Cooling method :- water cooling

Max. power consumption :- 1000W

Temperature setting range :- 0-300°C

Net weight :- 60Kg

Power supply :- 650W 220V, 50Hz

Dimension :- 570 × 520 × 670 mm

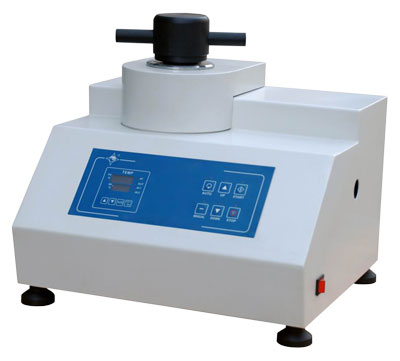

Fully Automatic Hot Mounting Machine RHM-5 Series

Automatic metallographic specimen mounting presses a kind of full automatic mounting press, equipped with in-out water cooling system. It is suitable for the heat mounting (thermo hardening & thermoplastic) for all kinds of materials. After the parameters such as heating temperature, heat preserving time and applied force etc. are set up, put the specimen and mounting material into the machine, close the cover and press the start button, then the machine will finish the job automatically. It is not necessary for the operator to be on duty. According to different requirment of the material, there are four kind of moulds that can be chosen to meet the demands as per requirement.

Technical Specifications:

Technical Specifications:

Diameter of specimen :- Ø25mm, Ø30mm, Ø40mm, Ø50mm

Cooling method :- Water cooling

Power Supply :- Single phase, 220V, 50Hz

Max. power consumotion :- 1800W

Setting range of system pressure intensity :- 0-2Mpa

Temperature setting range :- 0-300°C

Heat preserving time :- 0-99m-99s

Dimensions :- 615x510x500 cm

Net weight :- 110kg

Diameter of specimen :- Ø25mm, Ø30mm, Ø40mm, Ø50mm

Cooling method :- Water cooling

Power Supply :- Single phase, 220V, 50Hz

Max. power consumotion :- 1800W

Setting range of system pressure intensity :- 0-2Mpa

Temperature setting range :- 0-300°C

Heat preserving time :- 0-99m-99s

Dimensions :- 615x510x500 cm

Net weight :- 110kg

Auto Collimeter

AUTO COLLIMATOR is a sensitive, extremely accurate optical instrument which is precisely used in optical workshops, inspection departments and quality control labs.

It is basically a comparator where we compare optical element like slabs and prisms for flatness.

It is used for very small angle measurements of the order of minutes.

Specifications : -

Specifications : -

- Main Drum Division = 2 second

- Division on Reticle = 1 minute

- FL of Objective = 220mm

- Clear Aperture = 40mm

- Magnification = 11x

- Least Division on = 2" of arc Micrometer Drum

- Built in light source ,With 3 levelling screws in the base and suitable for measuring small angles Widely used in Metrological labs. It work on the principle light fall normally on mirror, the reflected ray comes back along the same path as the incident.

Angle Dekkor

'RADICAL' Precision Angle Dekkor is sensitive extremely accurate optical instrument which is precisely used in optical workshop. Inspection department and quality control labs.

APPLLICATIONS: It is basically a comparator where we compare optical elements like slabs

and all types of prisms for flatness and angles of prism in vertical plane

respectively. It is used for very small angle measurements of the order of

seconds.

APPLLICATIONS: It is basically a comparator where we compare optical elements like slabs

and all types of prisms for flatness and angles of prism in vertical plane

respectively. It is used for very small angle measurements of the order of

seconds.

Specifications : -

Specifications : -

- Focal Length of Objective : 220mm

- Clear Aperture of Objective : 40mm

- Magnification : 11X

- Measuring Range : 60-0-60 minute in X-Y axis.

- Least Division on Reticle : 1 minute of arc

- Least Division with Micrometer Drum : 2 second of arc

ELECTROLYTIC POLISHER Model REP-30

It is portable and can be used in Laboratory as well as in the Field.

FEATURES:-

FEATURES:-

TECHNICAL SPECIFICATION:

- Designed for rugged use in the Industrial atmosphere.

- No spillage of Chemicals and thus maximum yield of Electrolyte.

- Microstructure is prepared in single stage operation. Automatic change mode from polishing to etching.

- The process is skill free, and single man can handle the operation, as anode connection is in-built in pen type Probe. Pen type Probe with Fluid circulation is only required.

- The operation is quick reliable & produce TRUE MICRO STRUCTURE, on variety of Metals and Alloys.

- Overhead position will also be done vertical and other difficult position is possible to electro polish.

- Variable pump speed to overcome pitting problem commonly observed in Electrolytic polishing.

- To conduct ASTM practice A-262 "A" by NDT, to certify the quality of material

TECHNICAL SPECIFICATION:

| Supply Voltage | 230V AC. Power consumption when Polishing : 280W |

|---|---|

| Dimensions | Length (L) : 430 mm x Height (H) 330 mm x Width (W) 235mm. |

| Weight | 8 Kg. |

| (Empty w/o electrolyte) | |

| Pump Speed Control | Electronic (Infinite variable suitable for different metals and at different heights) |

| Polishing Voltage | 0-3 Amp |

| Polishing Timer | 0-90 Sec |

| Etching Voltage | 0-18 V |

| Polishing Power | 120 VA |

| Spares3 and 5 Amp | 5 Nos. each. Fuse |

| Spacer for Polishing | 10 Nos |

Hand Polisher Model RHP-30

| Polisher | Gun type, hand held having provision for adjustment of speed to suit specific requirement, complete with collate on which a Flexible Shaft having a collate fitted at 90° at one end, to which the Grinding wheels, Mops & Discs are fitted. |

|---|---|

| Wheels | Suitable grit grinding wheels are provided that can be fitted to the collate of the polisher and put to use. (2Nos.) |

| Mops | Specially designed of 60, 80 and 120 grit (4Nos. of each) |

| Lapping Disc | 30mm dia. specially designed, soft Rubber with provision for fitting to the collate of the flexible shaft, on which the paper/cloth are pasted, and put to use. (6pcs.) |

| Paper | 32mm dia. PSA backed paper 120, 220, 320, 400, 600, 800, 1000, 1200 (100 each). |

| Cloth | 32mm dia. Adhesive backed paper PC100, to be used for Alumina/Diamond Polishing (100pcs.) |

| Diamond | 5 gram. Syringe of 1micron along with 200ml. Aerosol can |

| Paste | Fluid (1 each) |

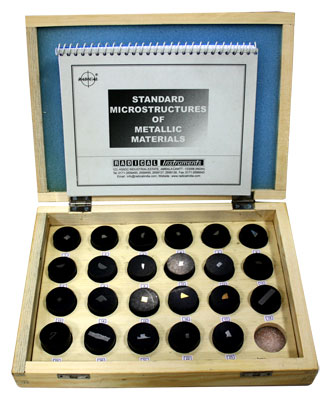

Standard Samples of Metal Structure

|

|

A Set Consists of 23 Standard Samples Which Covers The Entire Range I.E.

| Sample No. | Title | Sample No. | Title |

| 1. | Dead Mild Steel | 13. | Mottled Cast Iron |

| 2. | Low Carbon Steel | 14. | Ductile Cast Iron |

| 3. | Medium Carbon Steel (Annealing) | 15. | Cartridge Brass |

| 4. | Medium Carbon Steel (Normalizing) | 16. | Muntz Metal |

| 5. | Decarburised High Carbon Steel | 17. | Tin Bronze |

| 6. | Inclusion in Steel | 18. | Electroplated Component |

| 7. | Hardened Steel | 19. | Anodised Aluminium |

| 8. | Tempered Steel | 20. | Fusion Welded Mild Steel |

| 9. | Carburised Steel | 21. | Friction Welded Steel |

| 10. | Tool Steel | 22. | Powder Metallurgy Component |

| 11. | Grey Cast Iron | 23. | Deformed Mild Steel. |

| 12. | White Cast Iron |

Complete information including chemical composition, mechanical treatment, details of heat treatment, type of Etchant with description of Microstructure along with their coloured photographs are provided in a booklet. These sets are supplied in a wooden storing box with silica gel.

INSTRUMENTATION SINCE 1975 © 2024 Radical Scientific Equipments Pvt Ltd, All rights reserved